Powders are solvent-free paints, and are applied using an electrostatic system. The coating has a hard, even structure once it has been baked in the oven (~200°C).

Colour: RAL, NCS, Pantone, etc.

Satin, matte, glossy, textured, metallic finish.

Benefits

- High level of resistance to wear and tear (bad weather, UV radiation, etc. )

- Good coverage of edges

- Very easy to wash

- No drying time (baked in the oven)

- Treatment of large series

- High level of mechanical resistance

- Treatment of metal parts (steel, aluminium, stainless steel, galvanised steel, etc.)

- Wide range of colours (RAL, NCS, fluorescent colours, etc.)

- Smooth, matte, textured finish

- Non-pollutant ecological coating

- Satisfies EN1090, ACQPA and Qualisteelcoat standards

Available pre-treatments

- Sandblasting/Shot blasting

- Steel coated by thermal spraying

- Zirconium phosphate conversion coating

- Passivation

- Galvanising

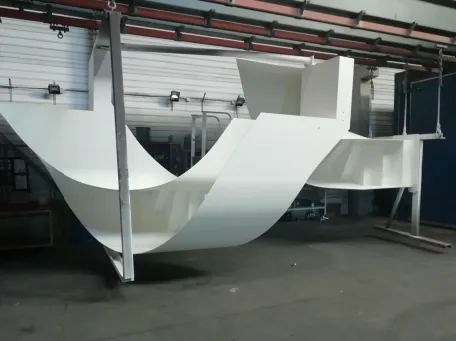

Capacities

- In an automated production line:

6000 mm x 2000 mm x 800 mm - 500kg - In a manual production line

12,000 mm x 3,000 mm x 3,000 mm – approximately 2 tons (extension possible up to 15,000 mm)