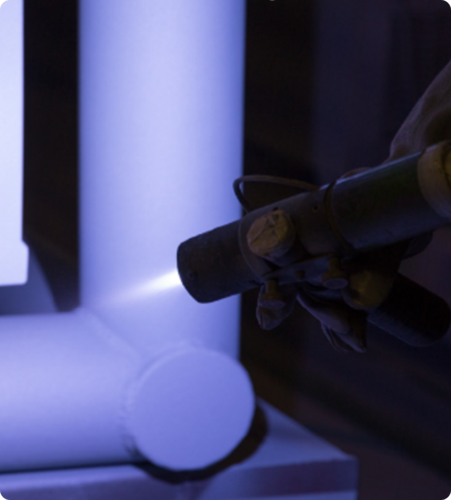

The Steel coated by thermal spraying process involves spraying zinc on a part. This consists of melting metal in the form of wire and spraying it on using an arc-spray gun..

The molten zinc cools rapidly on contact with the steel, forming an even, structured layer against rust and corrosion.

Benefits

- Offers long-term protection against corrosion and bad weather

- Parts treated in this way do not deform, as there is no thermal shock

- Offers good adhesion for future treatments

- Can be used to treat parts that cannot be galvanised

- An even layer (thickness ranging from 50µ to 120µ)

- Corrosion class C4 to C5X

- Satisfies EN1090, ACQPA and Qualisteelcoat standards

Capacities

- 20000 mm x 5000 mm x 6000 mm

- Maximum of 10 to 15 tons